Hi! Modern Wood Factory Operation Tour People use wood to make all sorts of things – in fact, it is a very literal cornerstone material. An example is that we use wood to make furniture, houses, buildings and even toys! But do you know how wood changes into furniture or toys? We are going to break down there this Intelligent production line for wooden doors from HRCK process one by one, step-by-step!

Raw wood gets passed through many steps before it is of any use. Wood is cut with a saw into specific shapes and sizes that are required first. Once the wood is cut, these pieces go to machines that assist in cutting them down into more precise shapes and smoothing out rough edges (sanders). A sander is a very unique piece of equipment because it has the ability to make your wood more velvety in feel. These panel furniture production line from HRCK work extremely carefully to give you a wooden, natural appearance of your blanket which feels very nice and soft.

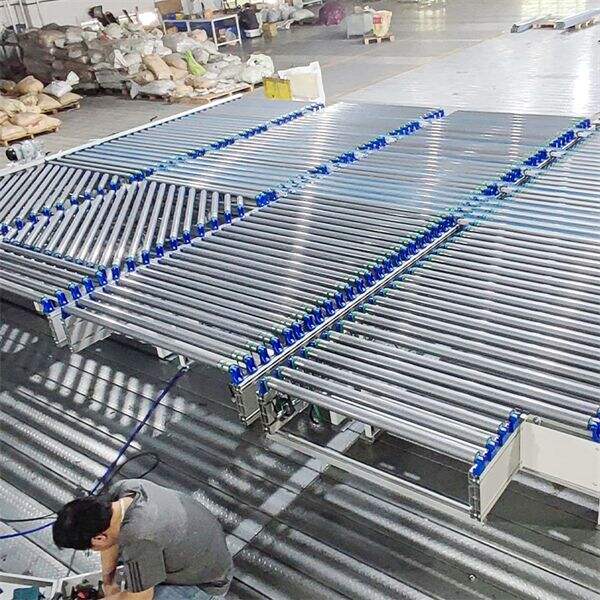

Hundreds of other pieces to the wood production technologies and machines, which are today extraordinarily advanced. These wood line from HRCK are capable of working at a much faster rate and more accurately than any person could ever do by hand. This includes, for example a computerised saw cutting several pieces of wood at once instead of one after the other. There are also Computer Numerical Control routers (CNC) which carve out intricate and artistic patterns from the wood. What this also means, is that the wood can structurally appeal very nice and unique. Workers in the factory, as well as machines, can be seen using hammers to sculpt detail and features from the wood. Those masterpiece making tools are helpful to the workers in putting their skills and creativity into those wood products.

Quality control is a key factor when it comes to manufacturing timber products. This woodworking automatic line enforces the durability and look of your products. The wood is also inspected for defects by workers on quality control. That means they inspect for cracks, chips and other issues that could have an impact on the quality of what is ultimately produced. They check the wood to verify that it does not meet its definition of suitable. If everything is perfect, then you are applied special chemicals which make them safe and gives a beautiful tinge upon seeing. These treatments help to protect the wood and enhance its appearance. So when you are rustic furniture shopping, you can have peace of mind that your handmade natural wood furniture is good-to-go.

For instance, they will plant new trees when old ones are cut down. This keeps the forest alive and burgeoning. These mills also employ selective logging practices so they can only take down a couple trees at a time instead of cutting across an entire area. The panel furniture product line also provide ways to help the environment by recycling wood waste such as sawdust into new product. That way, they make the best possible use of the wood and reduce waste.

We Wood production line developed a substantial amount of knowledge in the woodworking sector within Foshan Nanhai Honorgrui Machinery Manufacturing Company, Ltd. We have been delivering custom automation solutions for woodworking operations since our founding. From conveyor systems to processing equipment We have the experience of understanding their particular requirements. Our team is highly knowledgeable of the challenges and requirements of production woodworking. With years of experience in the industry, we design and provide robust, reliable automation systems which improve efficiency of production and quality of the product. Our knowledge of the industry not only helps clients optimize their processes for production, but also tackles many technical issues that are specific to industry and ensures that every system is perfectly aligned with woodworking needs. We can provide you with assistance in the woodworking sector and give your production line a competitive edge.

Foshan Nanhai Hongrui Machinery Manufacturing Co., Ltd. is at the forefront of manufacturing automation technology. With over a decade's experience, we have a specialization in developing, manufacturing, and constructing a broad range of automation solutions, including conveyor belts as well as roller lines and gantry feeders. Our products are constantly improved and we launch new products every year to keep up with the ever-changing needs of the market. Our commitment to quality is reflected in our Wood production line, TUV, SGS, and ISO certifications, ensuring the highest standards of quality and performance. You will benefit from our top-of-the-line technology and products that maximize efficiency and high-quality.

More 10 engineers collaborate to develop innovative products that keep up market dem s provide customized solutions that meet the specific requirements continuously improving products research into technology Our strong RD capabilities not only advance technology but also keep edge in the market deliver efficient reliable automation solutions that break the boundaries of traditional technology leading Wood production line trends This ensures the highest performance for every product create

Our extensive after-sales assistance includes installation, commissioning, and maintenance. Our customer service staff is highly educated and is Wood production line to respond to any problems that may occur. With our global support network We provide prompt technical support and solutions no matter where you are. We're committed to providing professional and efficient service that ensures long-term reliability of your equipment. This will enhance efficiency in production and ensure satisfaction for customers. We take your requirements into consideration and aim to meet your expectations with each service we offer.