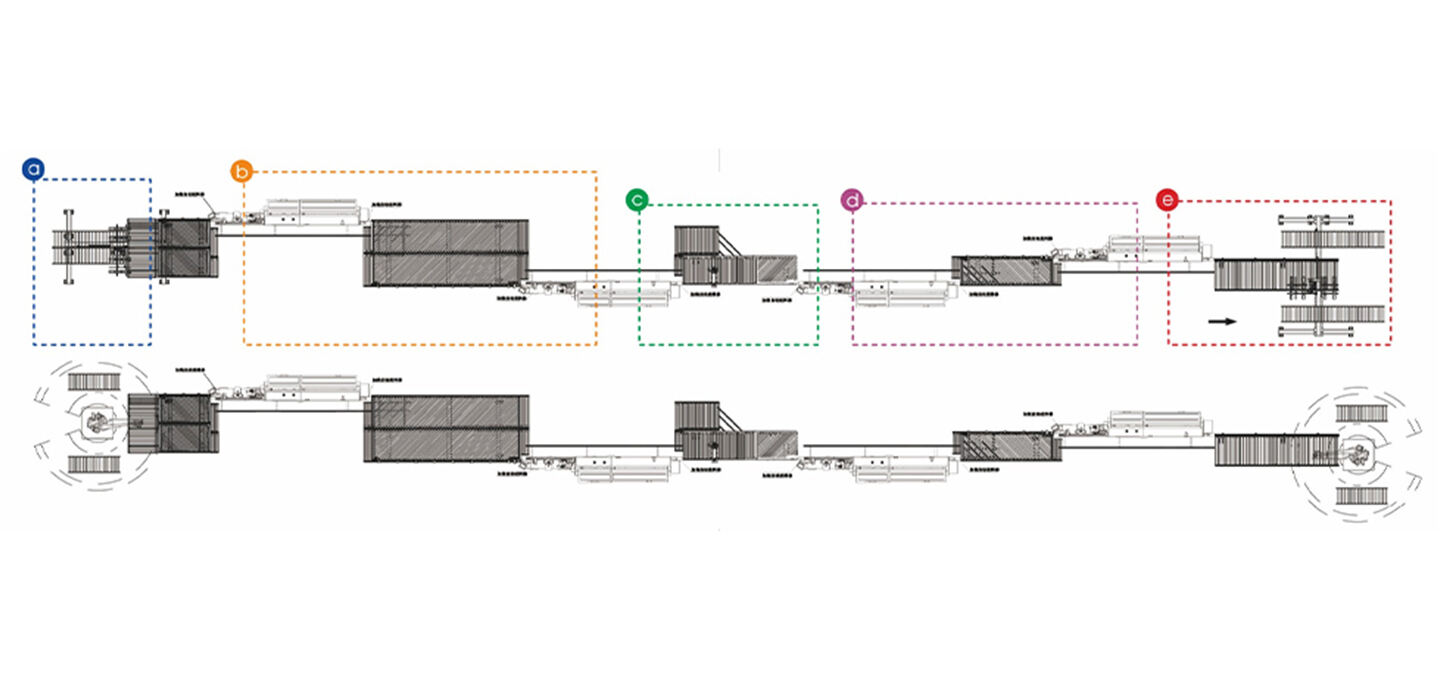

Edge Banding Machine Connection

1. The main beam is made of high-strength aerospace aluminum, whichmeets the ICE6113l internatlonal standard

2. The roller adopts German high-strength cutting-resistant 2mm sleeverubber process

3. Electric parts adopt German brand Schider

4. Adopt Talwan Delta Detla PLC control system

5.Pneumatic components adopt Talwan yadek

6.American Carlisle rubber timing belt drive, no nolse, smooth transmisslon

7. The upper and lower cones are covered with $wedish PU soft rubber, andthe size can be customzed

8. ltaly Libo elastic belt and timing belt drlve, smooth and low nolse

| Main parameters | |||

| Working height | 950±50mm | Workpiece thickness | 10-60mm |

| Workpiece length | 200~2800mm | Max Load | 100kg |

| Workpiece width | 200~1220mm | Speed | 14-40 (M/min) |