The HRCK’s Wear-Resisting Pu Lamination Polyurethane Rice Mill Rubber Coated Plastic Roller With Steel Shaft For Conveyor System is certainly an ideal commercial conveyor component to produce better and dependable product transportation. This roller was engineered with wear-resistant which can withstand heavy materials and even the high abrasive surroundings, which makes it an ideal option for the demanding applications such as rice milling.

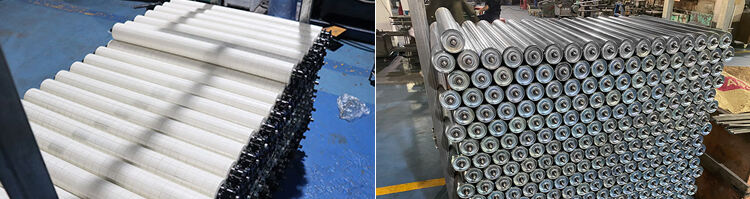

The roller's polyurethane layer supplies a smooth and non-slip area efficient for product motion, while its synthetic core adds further durability and strength. This roller's unique construction provides superior opposition to damage resulting in less replacements and reduced maintenance expenses.

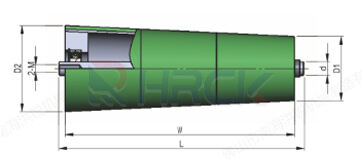

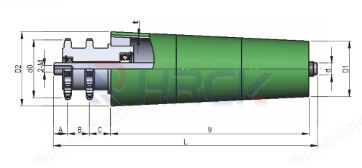

It comes with a metal shaft that insures security and power during procedure. Its design precision-engineered permits to move efficiently and quietly, preventing unneeded vibrations that can harm the conveyor system and decrease effectiveness.

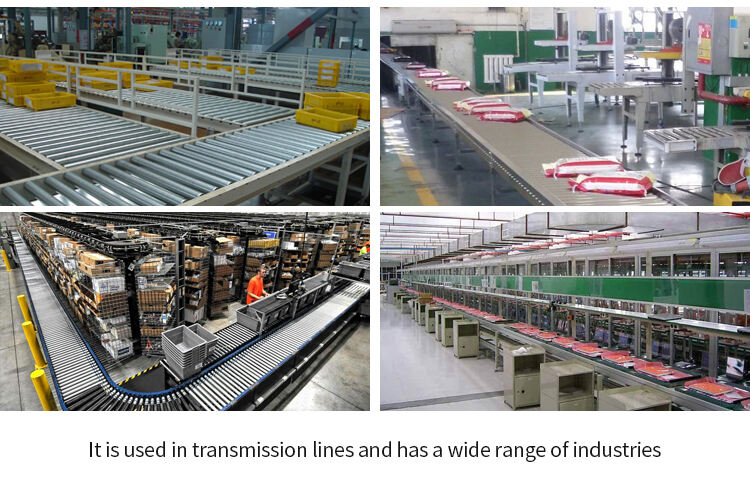

This item is the perfect solution whether you need to transport big examples of rice and other heavy materials, or items with razor-sharp sides that can harm traditional rollers. This roller works together with by having a selection of conveyor systems, making this a versatile and economical option to any industry which will provide efficient product transport.

The HRCK brand is well-known for its quality and dependable products, and this isn't any exclusion. Each roller had undergone trials and tests to make sure that it satisfies the greatest criteria of gratification and durability. This product features a comprehensive maker, offering clients satisfaction and self-confidence in their purchase.

Customizable content |

||||||||

Various sizes |

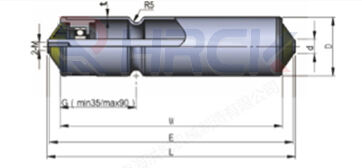

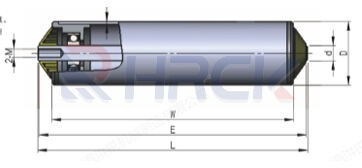

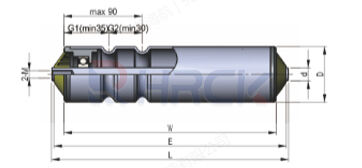

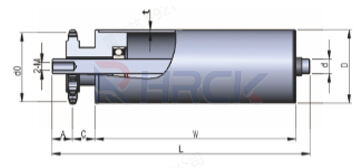

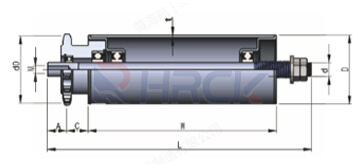

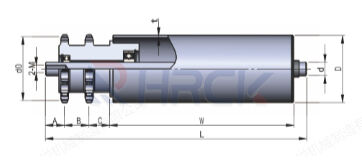

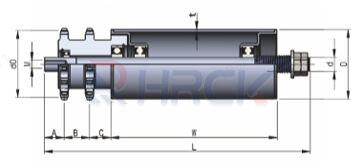

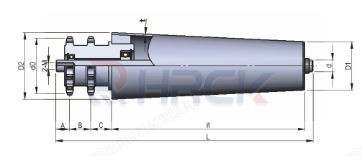

Pipe diameter(D),Shaft diameter(d),Roller length(W) |

|||||||

Shaft end size |

1.Round shaft 2.Milling

3.Milling a semicircle

4.internal thread

5.External thread

6.Split pin shaft

7.Hollow tube shaft

8.Hexagonal shaft

|

|||||||

Material |

1. Stainless steel 2. Carbon steel

3. Aluminum alloy

4. Plastic

|

|||||||

Surface treatment |

1. Galvanized 2. Plating and soldering

3. Plastic encapsulation

|

|||||||

Roller shape |

1. Unpowered 2. Single slot O belt

3. Double groove O belt

4. Single chain

5. Double strand5. Cone roller

|

|||||||