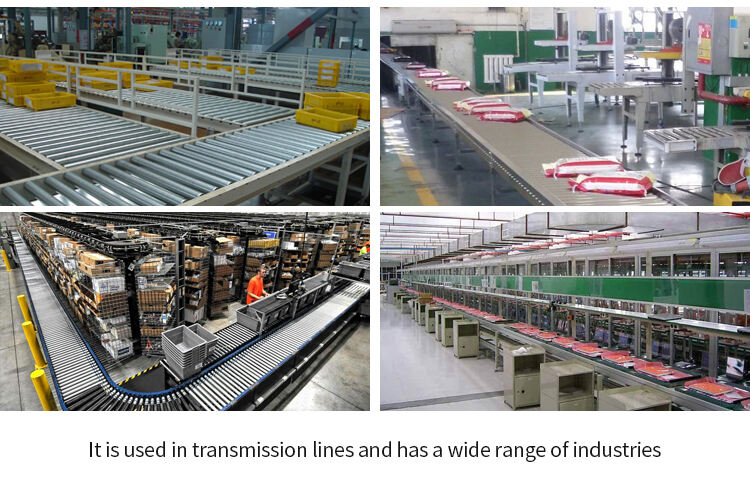

If you ought to be looking for an idler high-quality for the devices, look no more as compared with HRCK Stainless Steel Idler Roller Chrome Plated Steel Roller. The item developed high-grade create your devices operate much a lot extra efficiently as well as efficiently, assisting you conserve important money as well as opportunity.

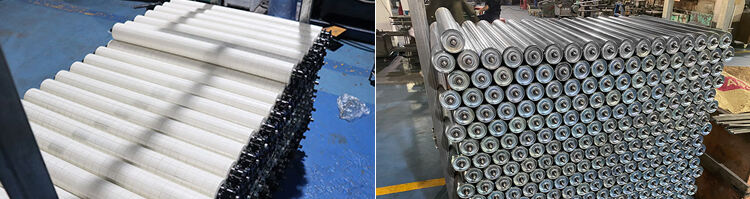

The HRCK Stainless Steel Idler Roller Chrome Plated Steel Roller is offered along with a soft, brightened location produced far from high-quality steel stainless. This item resilient immune towards rust as well as utilize, significance that therefore it will certainly final a lot longer as well as carry out a great deal much a lot better compared to various other rollers that are idler on the marketplace. And also, the steel chrome-plated offers a lot more safety and safety up immune towards the aspects, causing this to become roller perfect for utilize within severe environments where various other rollers might separate or even deteriorate quicker.

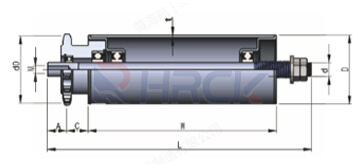

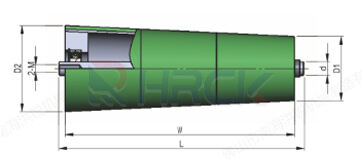

Among the essential leading functions of the HRCK Stainless Steel Idler Roller Chrome Plated Steel Roller is its own precision design. The roller is created towards suit totally into the devices, creating specific it runs effectively along edge very little resonance. This certainly not just enhances the efficiency of this particular equipment and extends its own life expectancy, as resonance might trigger utilize very early tear on various other aspects.

The HRCK Stainless Steel Idler Roller Chrome Plated Steel Roller could be rather extremely simple towards set up as well as maintain preserving along edge its own resilience as well as precision. The roller consists of every one of the devices required standards, it as well as running rapidly to obtain. When established, the roller needs maintenance very little exactly just what this implies is much less downtime for the equipment as well as much more effectiveness for your demands.

Customizable content | ||||||||

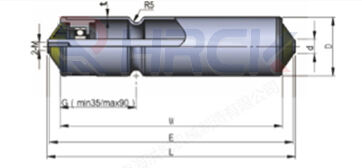

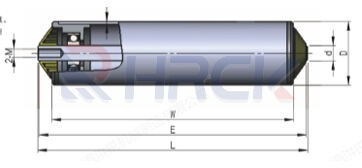

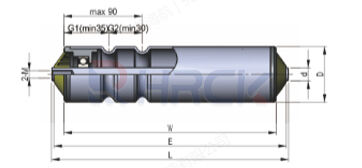

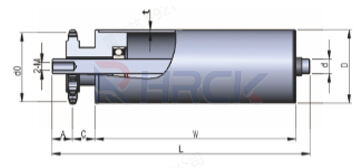

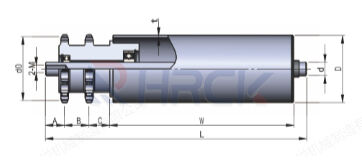

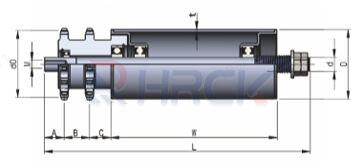

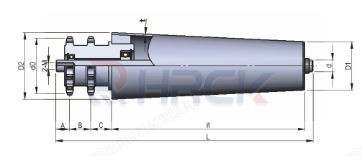

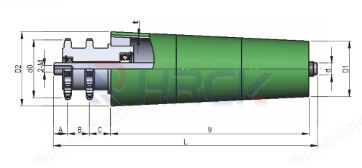

Various sizes | Pipe diameter(D),Shaft diameter(d),Roller length(W) | |||||||

Shaft end size | 1.Round shaft 2.Milling 3.Milling a semicircle 4.internal thread 5.External thread 6.Split pin shaft 7.Hollow tube shaft 8.Hexagonal shaft | |||||||

Material | 1. Stainless steel 2. Carbon steel 3. Aluminum alloy 4. Plastic | |||||||

Surface treatment | 1. Galvanized 2. Plating and soldering 3. Plastic encapsulation | |||||||

Roller shape | 1. Unpowered 2. Single slot O belt 3. Double groove O belt 4. Single chain 5. Double strand5. Cone roller | |||||||