Customizable content | ||||||||

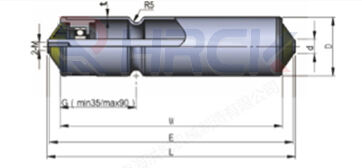

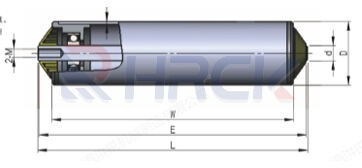

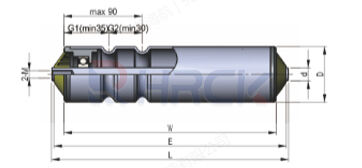

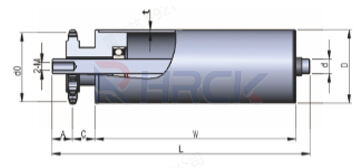

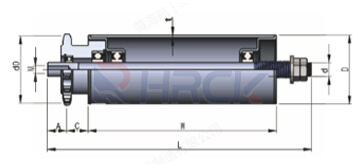

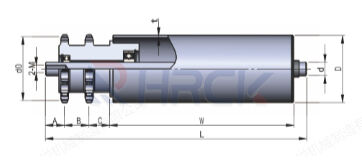

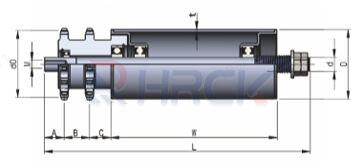

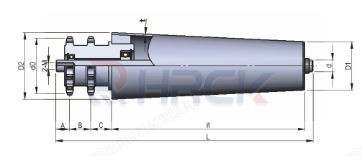

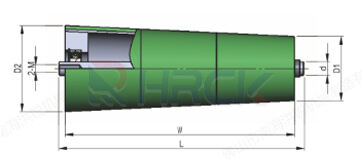

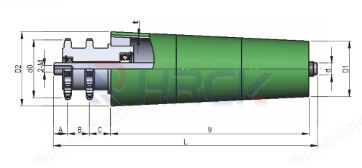

Various sizes | Pipe diameter(D),Shaft diameter(d),Roller length(W) | |||||||

Shaft end size | 1.Round shaft 2.Milling 3.Milling a semicircle 4.internal thread 5.External thread 6.Split pin shaft 7.Hollow tube shaft 8.Hexagonal shaft | |||||||

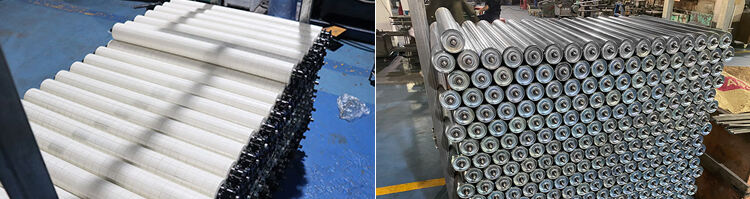

Material | 1. Stainless steel 2. Carbon steel 3. Aluminum alloy 4. Plastic | |||||||

Surface treatment | 1. Galvanized 2. Plating and soldering 3. Plastic encapsulation | |||||||

Roller shape | 1. Unpowered 2. Single slot O belt 3. Double groove O belt 4. Single chain 5. Double strand5. Cone roller | |||||||

HRCK

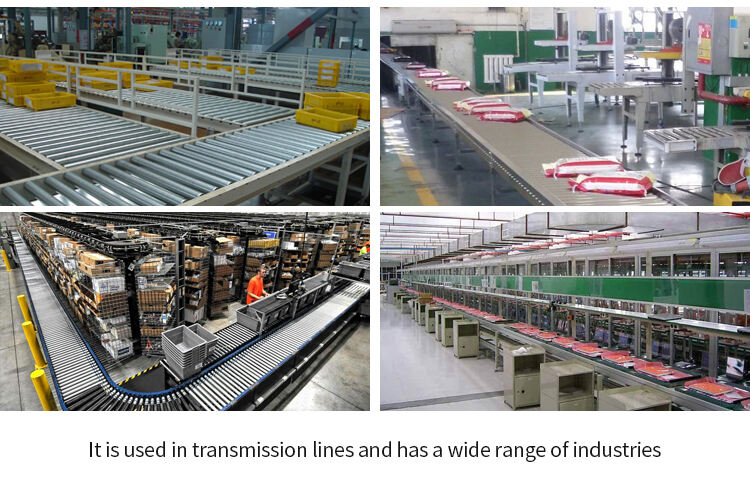

Introducing Quality Conveyor Equipment Drive Rollers With Single-Row And Double-Row Sprockets In Plastic Or Steel Design, Roller from HRCK. These innovative drives are expertly fashioned with single-row and double-row sprockets, obtainable in both synthetic and steel designs. These drive rollers would be the epitome of durability, efficiency, and dependability, ensuring your conveyor system functions smoothly and flawlessly.

The HRCK Quality Conveyor Equipment Drive Rollers With Single-Row And Double-Row Sprockets In Plastic Or Steel Design, Roller are manufactured with exceptional requirements making to withstand the toughest conditions that are working industries that are various as for instance logistics, manufacturing, automotive, and many other things. These drive rollers are constructed from premium-grade rugged materials and are resistant to abrasion, impact, and corrosion, ensuring safety durability long lasting.

The HRCK Quality Conveyor Equipment Drive Rollers With Single-Row And Double-Row Sprockets In Plastic Or Steel Design, Roller offer ample versatility the single-row and sprockets that are double-row the installation and maintenance procedure. The sprockets are manufactured to improve the effectiveness of your conveyor system by reducing energy and optimal the chances of slippage. Single-row sprockets are recommended for lighter loads, whilst the double-row sprockets handle heavier loads with ease.

In addition, these Quality Conveyor Equipment Drive Rollers With Single-Row And Double-Row Sprockets In Plastic Or Steel Design, exceptional Roller available in both synthetic and metal designs, which offer comparable features and benefits with slight differences in their functionality. The plastic drive is lighter, more flexible, and quieter while running compared to the metal drive rollers. The metal drive rollers tend to be more robust and have significantly more load-bearing capacity, making them ideal for heavy-duty applications on the other hand.

The HRCK Quality Conveyor Equipment Drive Rollers With Single-Row And Double-Row Sprockets In Plastic Or Steel Design, Roller are compatible with various conveyor systems, making them a business's option that are versatile. Whether you're looking to upgrade your conveyor lines, replace old and damaged drive rollers, or start a brand-new project, HRCK gets the most readily useful solution which will suit your purposes and surpass your expectations.