Hongrui Conveyor Machinery Steel Tube Tapper Cone Conveyor Roller is just a item top-quality to meet up with the requirements of clients in to the product industry managing. This product is manufactured by HRCK, a brandname recognized for the dedication to creating conveyor top-tier dependable, durable, and efficient.

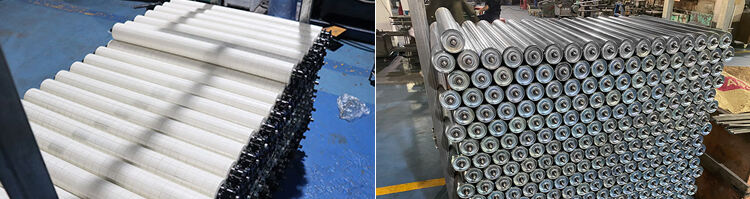

The Hongrui Conveyor Machinery Steel Tube Tapper Cone Conveyor Roller is made from premium quality metal tubing, making certain this system will withstand lots that are hefty usage constant bending or breaking. This will ensure it is a great item for different commercial applications where durability is simply a problem top.

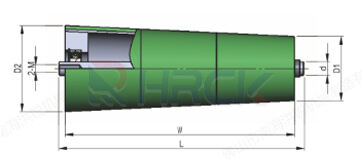

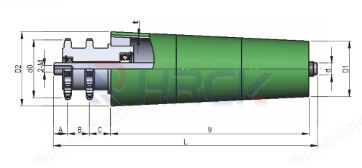

One of the standout top popular features of this system will be the tapper cone design, rendering it simple for the conveyor gear to align because of the roller. This outcomes in smoother and even more efficient conveyor operations, decreasing the damage of this gear and enhancing the durability when it comes to system general. Furthermore, the cone design additionally decreases sound amounts during procedure, developing a quieter environment working workers.

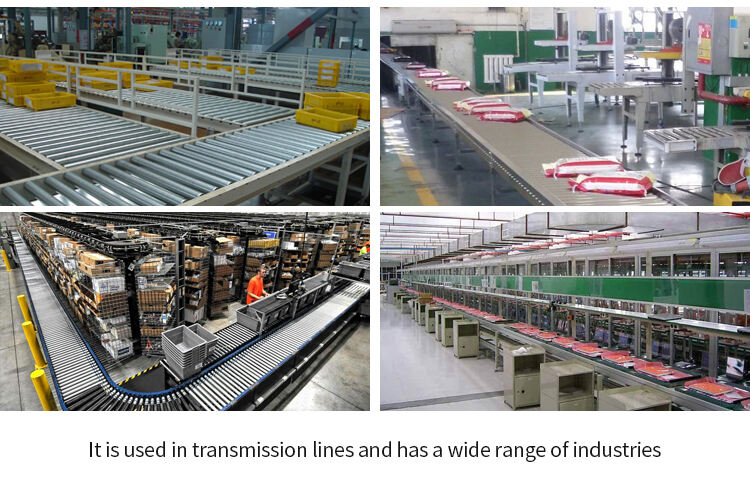

The Hongrui Conveyor Machinery Steel Tube Tapper Cone Conveyor Roller features a true number of applications in companies such as for instance mining, construction, and delivery. These rollers are specifically beneficial in conveyor systems that run in harsh conditions, such as for example conditions that are high dusty surroundings, and moisture high. The product’s design robust it appropriate these surroundings and implies that it could manage the needs of heavy-duty applications.

Installation related to Hongrui Conveyor Machinery Steel Tube Tapper Cone Conveyor Roller is straightforward and can be performed quickly. The product works together with conveyor systems which are many, making it an easy task to incorporate into current operations without the necessity for expensive and time intensive adjustments.

Customizable content |

||||||||

Various sizes |

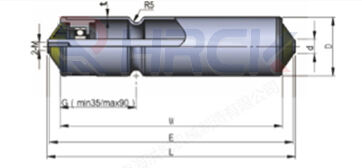

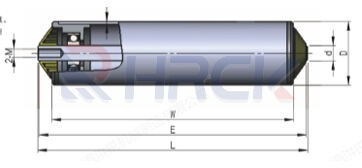

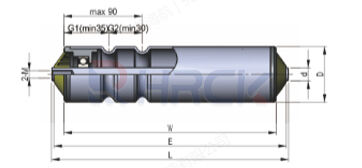

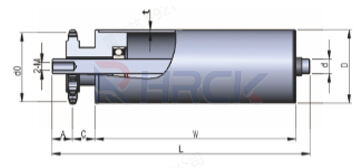

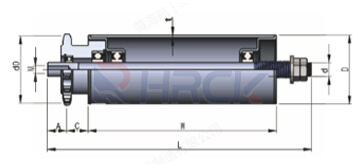

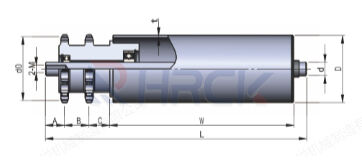

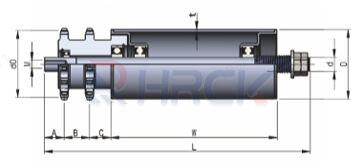

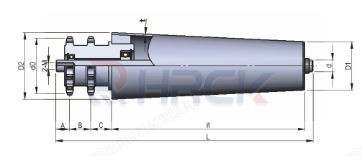

Pipe diameter(D),Shaft diameter(d),Roller length(W) |

|||||||

Shaft end size |

1.Round shaft 2.Milling

3.Milling a semicircle

4.internal thread

5.External thread

6.Split pin shaft

7.Hollow tube shaft

8.Hexagonal shaft

|

|||||||

Material |

1. Stainless steel 2. Carbon steel

3. Aluminum alloy

4. Plastic

|

|||||||

Surface treatment |

1. Galvanized 2. Plating and soldering

3. Plastic encapsulation

|

|||||||

Roller shape |

1. Unpowered 2. Single slot O belt

3. Double groove O belt

4. Single chain

5. Double strand5. Cone roller

|

|||||||