HRCK

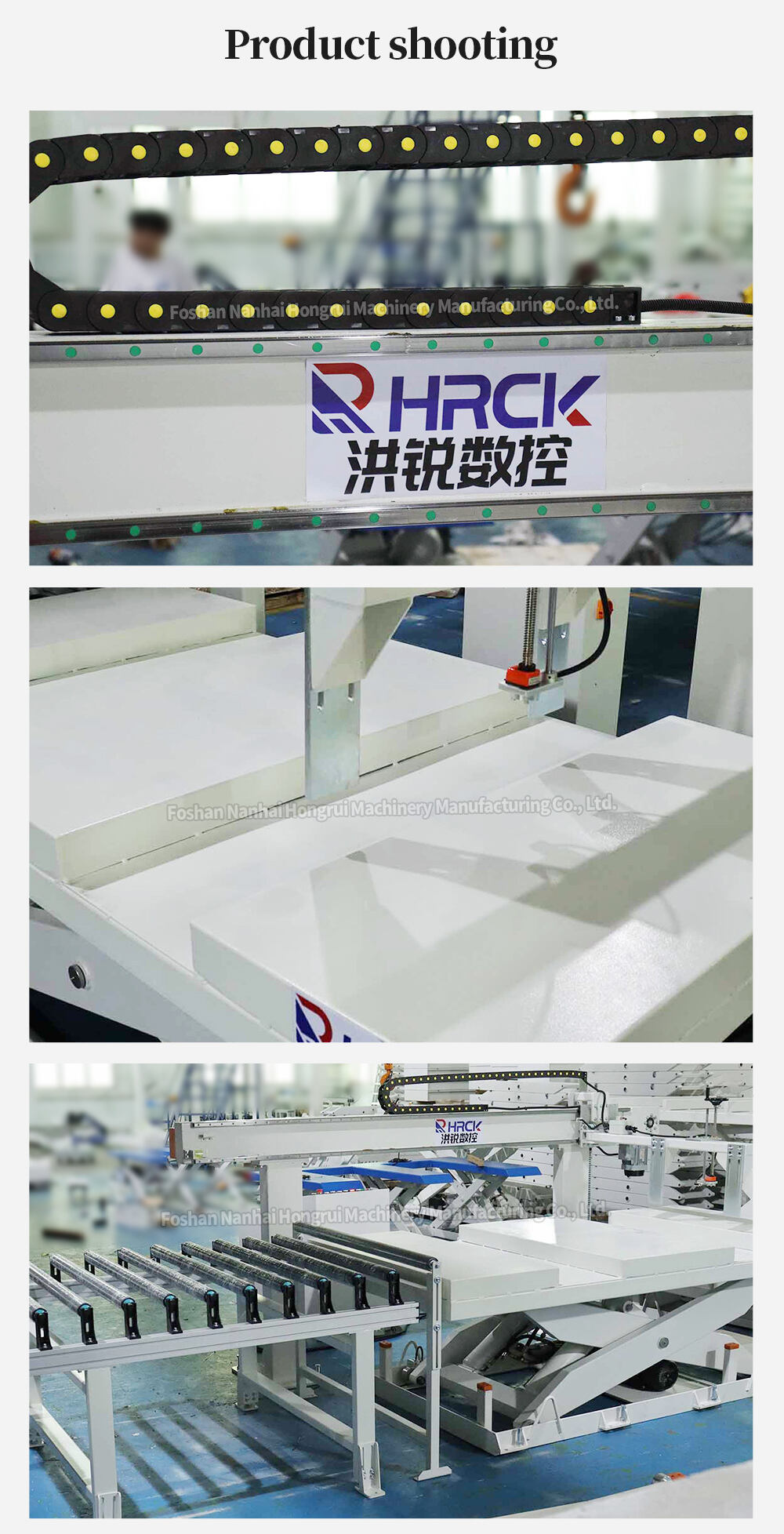

The HONGRUI Automatic Push Plate Feeder Machine for CNC Cutting Saw Machines Computer Beam Saw for Panel Size are an revolutionary and item versatile to make the cutting procedure easier and a lot more efficient. Manufactured, this push dish feeder device is made to fit seamlessly with CNC cutting saw devices make it easy for quicker and much more cutting accurate of sizes.

The HONGRUI Automatic Push Plate Feeder Machine for CNC Cutting Saw Machines Computer Beam Saw for Panel Size from HRCK is a addition ideal a selection of companies that require high accuracy cutting of panel sizes. This product is efficient, user-friendly, and dependable, that makes it a popular among cutting experts. It truly is ideal for use within the woodworking industry, furniture production, and construction industry.

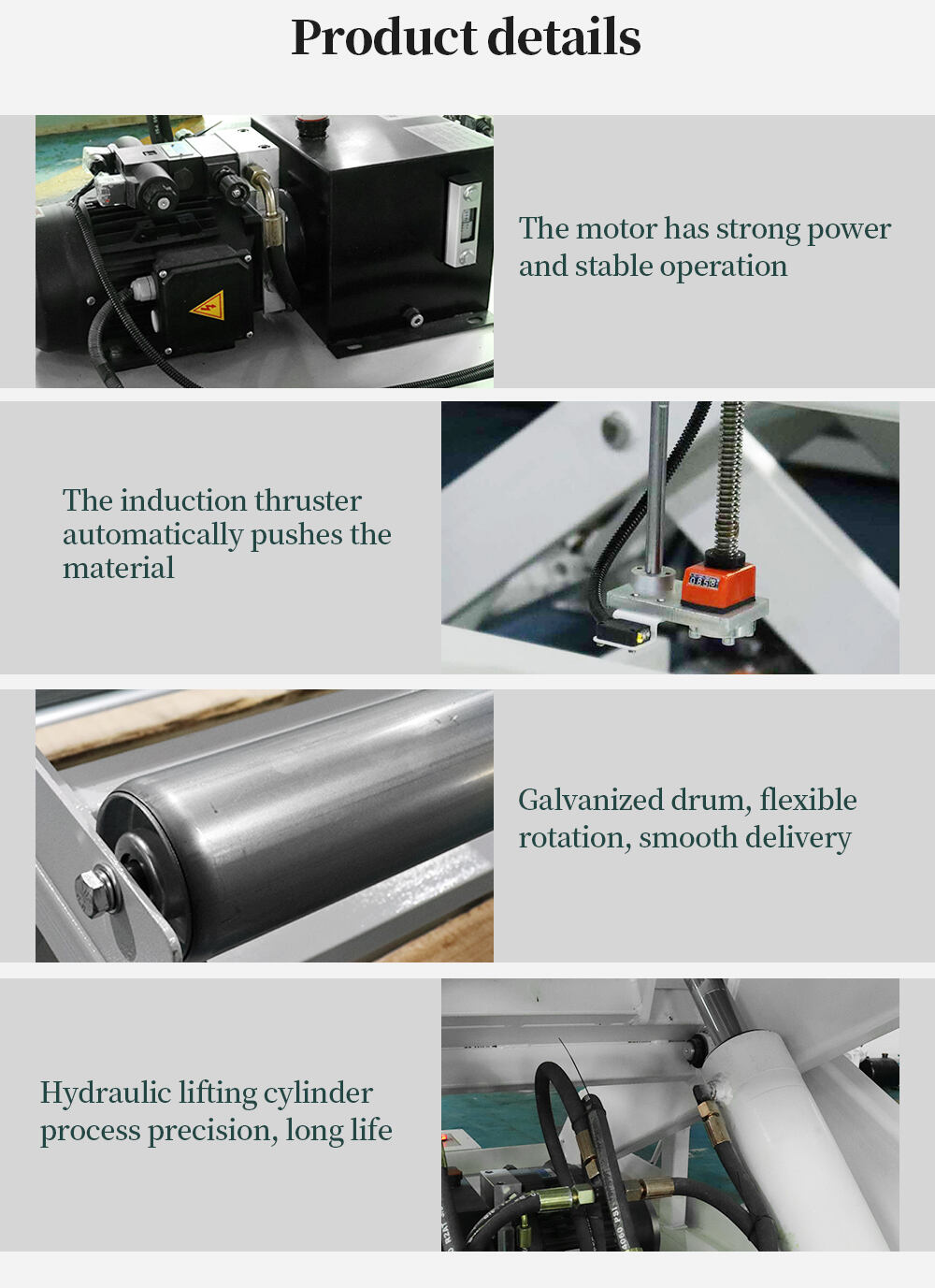

Among the standout options that come with this operational system is it is completely automatic. It features a push exclusive system that permits the operator to feed the panel size in to the cutting saw machines with simplicity. This particular feature eliminates the dependence on manual handling for the panel big, which improves security within the workshop. Additionally improves efficiency by decreasing the time best taken fully to load and unload panel sizes.

The HONGRUI Automatic Push Plate Feeder Machine for CNC Cutting Saw Machines Computer Beam Saw for Panel Size can be customizable. It’s built to fit a selection of CNC cutting saw devices, and it will be modified to guide panel significantly different. Its side-pressure rollers offer even stress along the distance whole of panel to make sure accurate cuts each and each time.

This device normally quite easy to keep. It comes down insurance firms an individual well-detailed providing you with step-by-step directions in the way best to make use of and keep the push dish feeder. The apparatus is made with top-notch elements to be sure a lengthy solution life, it’s developed to need upkeep.

Product name | ||||||||

Conveying capacity | Customizable | |||||||

Conveying distance | Customizable | |||||||

Overall dimensions | Customizable | |||||||

weight | Customizable | |||||||

weight | Mechanical accessories | |||||||

Pre-sales | In-depth understanding of customer needs, professional team customization | |||||||

On sale | Professional team shall conduct on-site installation, and conduct the whole line commissioning after installation | |||||||

After sales | The professional after-sales team continues to provide follow-up services, and provides long-term automation upgrade consulting services | |||||||