Սա մեկը, որտեղ մենք սpielալու ենք ինչ-որ բան այնքան հաճախակի է: մեծ մեքենաներ, որոնք շարժում են փոխադրությունները շուրջ կապույտ արտադրանքների տարածքով գենտրի (RTG) մեքենաներ Դա կարևոր մաս է այն գործը, որը մենք շարժում ենք մեր արտադրանքները մեծ անձերից տարածք:

ԴՐՈՒԳ ԿԱՐԳԱՑՎԵԼ

Բարև, ընկերներ! Ցանկանու՞մ եք իմանալ մանրակարգ տարածքով գենտրի կրեների մասին? Այս մեքենաները այնքան արտահայտ են, որ օգնում են ավելացնելու և շարժելու անվանական արտադրանքները: Այս հոդվածում մենք կսովորենք այս կրեների վերագին ընկերությունները Պորտուգալիայում...

ԴՐՈՒԳ ԿԱՐԳԱՑՎԵԼ

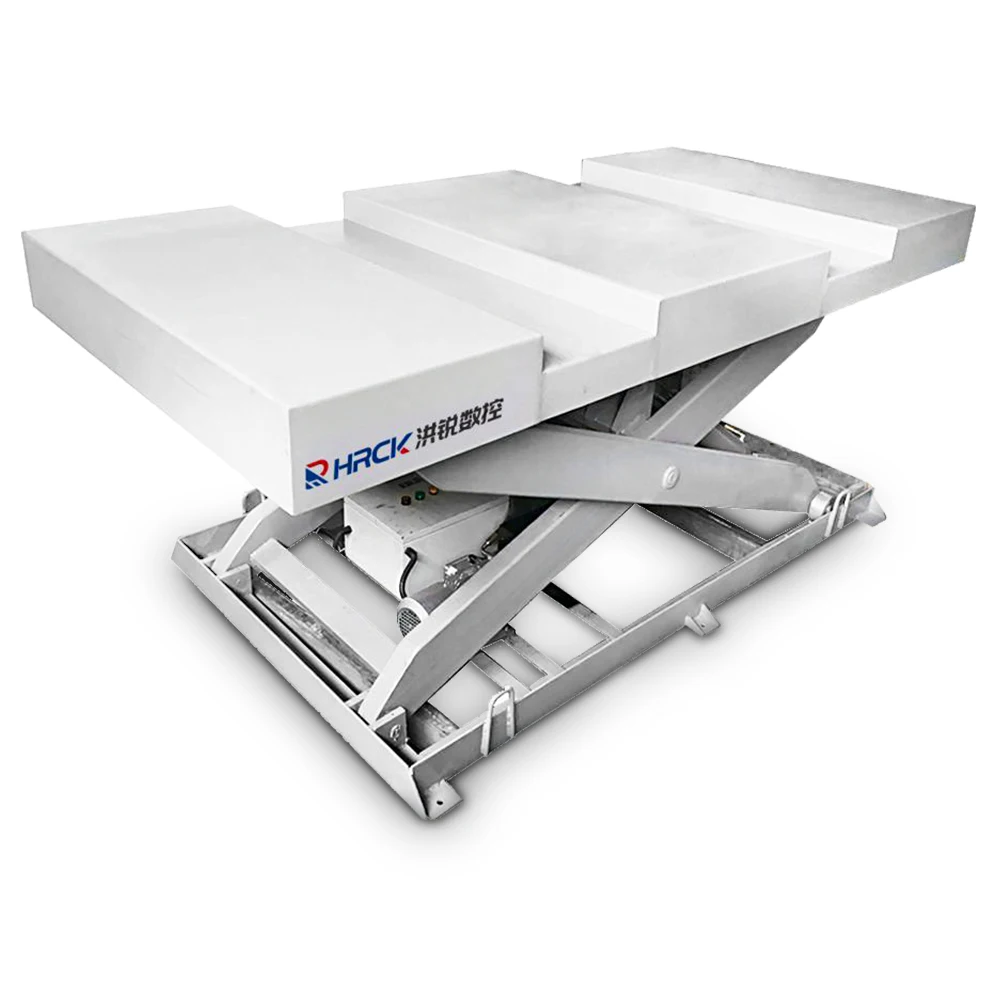

HRCK-ն արդյունաբերության առաջատար ընկերություն է և արտադրող՝ Լիտվայի Հանրապետությունում գտնվող իր բարձրորակ ռոլիկային ավտոմատացված ֆաբրիկայի լուծումներով: Ուշադրություն դարձնելով որակին և արդյունավետությանը՝ HRCK-ն արագ վստահելի անվանում դարձավ այս ոլորտում: Ավելի քան 10 տարվա...

ԴՐՈՒԳ ԿԱՐԳԱՑՎԵԼ

Երբ խոսքը գալիս է փիլիների կտրող մեքենաների մասին Դանիայում, HRCK-ն բոլորի առաջնահերթ ընտրությունն է: Մեր արտադրանքները նախատեսված են մեծածախ գնորդների համար, ովքեր պետք է որակյալ մեքենաներ ձեռք բերեն՝ իրենց արտադրողականությունն ու ընդհանուր գործունեությունը բարձրացնելու համար: Սակայն HRCK-ի ընտրությամբ...

ԴՐՈՒԳ ԿԱՐԳԱՑՎԵԼ

Hongrui սարքավորումների մասին՝ Ձեր վստահելի ավտոմատացման գործընկերը: Հիմնադրված 2013 թվականին՝ Ֆոշան Նանհայ Հոնրուի սարքավորումների արտադրության ընկերությունը ամրապնդված հեղինակություն է ձեռք բերել որպես ֆաբրիկաների ավտոմատացման լուծումների մասնագիտացված մատակարար՝ ներառյալ բարձր որակի ֆաների...

ԴՐՈՒԳ ԿԱՐԳԱՑՎԵԼ

Ավտոմատացման մեջ հաջողության ժառանգություն. Հիմնադրված 2013 թվականին՝ Ֆոշան Նանհայ Հոնրուի սարքավորումների արտադրության ընկերությունը ավելի քան տասնամյակ շարունակ մասնագիտացված փորձագիտական գիտելիքներ է մատուցել գլոբալ շուկայում՝ ներառյալ Մադագասկարի աճող փայտամշակման արդյունաբերությունը: Մենք նվիրված ենք...

ԴՐՈՒԳ ԿԱՐԳԱՑՎԵԼ

Այնքան որ սիրում եք տանգային աշխատանք, հավանաբար գիտեք, որ լավացնումը պրոցեսի հիմնական մաս է: Երբ դուք լավացնում եք, դա իրականում դարձնում է կտորը անգամ հավանական և ավելի հարմար է նայել: Այո, դրանք չնայած կարող են դառնալ ավելի գեղեցիկ նայելուց հետո լավացնելուց հետո...

ԴՐՈՒԳ ԿԱՐԳԱՑՎԵԼ

Երկրավորում եք արդյոք դժվար մեխանիկական գործիք՝ ձեր միջոցները բարձրացնելու համար աշխատանքային սենյակում? Եթե պատասխանը այո է, ապա անհրաժեշտ է նայել 8 Լավագույն 2 Կողմին Հաստատունների Մատակարար Բրազիլիայում! Ծուգահանդիս՝ Սա լավ հաստատուններ են, որոնք օգնեն ձեզ ձեր աշխատանքը ավելի հեշտ դարձնելու համար...

ԴՐՈՒԳ ԿԱՐԳԱՑՎԵԼ

Դուք երբեք եք տեսել շարժվող տրանսպորտատոր տուփերի համար, որոնք նաև այսպես հայտնի են այս բաներով մալուում? Սա միակ տեսակ տրանսպորտատոր տուփն է, որը վերցնում է ձեր տուփերը մալու շուրջ, որպեսզի դուք կարող լինեք ավելի ազատ գնահատել: Բայց գուցե ի՞նչ, շարժվող տրանսպորտատորները չեն միայն մալուում...

ԴՐՈՒԳ ԿԱՐԳԱՑՎԵԼ

Արդյոք երբեմն մտածել եք, թե ինչպես փոխանցվում են փաթեթները և օբյեկտները մեկ վայրից մյուսը մեծ գործkedանում կամ ապահովանում։ Այստեղ մեզ կարող են օգնել ռոլային փոխանցիչները։ Դրանք ենթադրական մեքենաներ են, ինչպես ռոլներ, որոնք պարզապես պտտվում են և կուտակում են բանալիք։

ԴՐՈՒԳ ԿԱՐԳԱՑՎԵԼ

Հարուկի Մեքենաշինություն (HRCK) Ալժիրում գլխատախտակի փոխադրողներ արտադրող ընկերությունների շարքում համարվում է որակի տեսանկյունից ամենալավ մատակարարներից մեկը։ HRCK-ի ուշադրությունը նվիրված է նորագույն տեխնոլոգիաներին և մրցունակ գներին, ինչը դարձնում է այն...

ԴՐՈՒԳ ԿԱՐԳԱՑՎԵԼ

Փոխանցիչները որոշ միակ մեքենաներ են, որոնք յուրաքանչյուր վայրից մյուսը փոխանցում են ապարատներ։ Դրանք անհրաժեշտ են, քանի որ օգնում են տեղափոխել ավելի անվանական բանալիք։ Եգիպտում դուք կգտնեք փոխանցիչներ почти տարածված են և mooieնում ավարտական համակարգեր...

ԴՐՈՒԳ ԿԱՐԳԱՑՎԵԼ