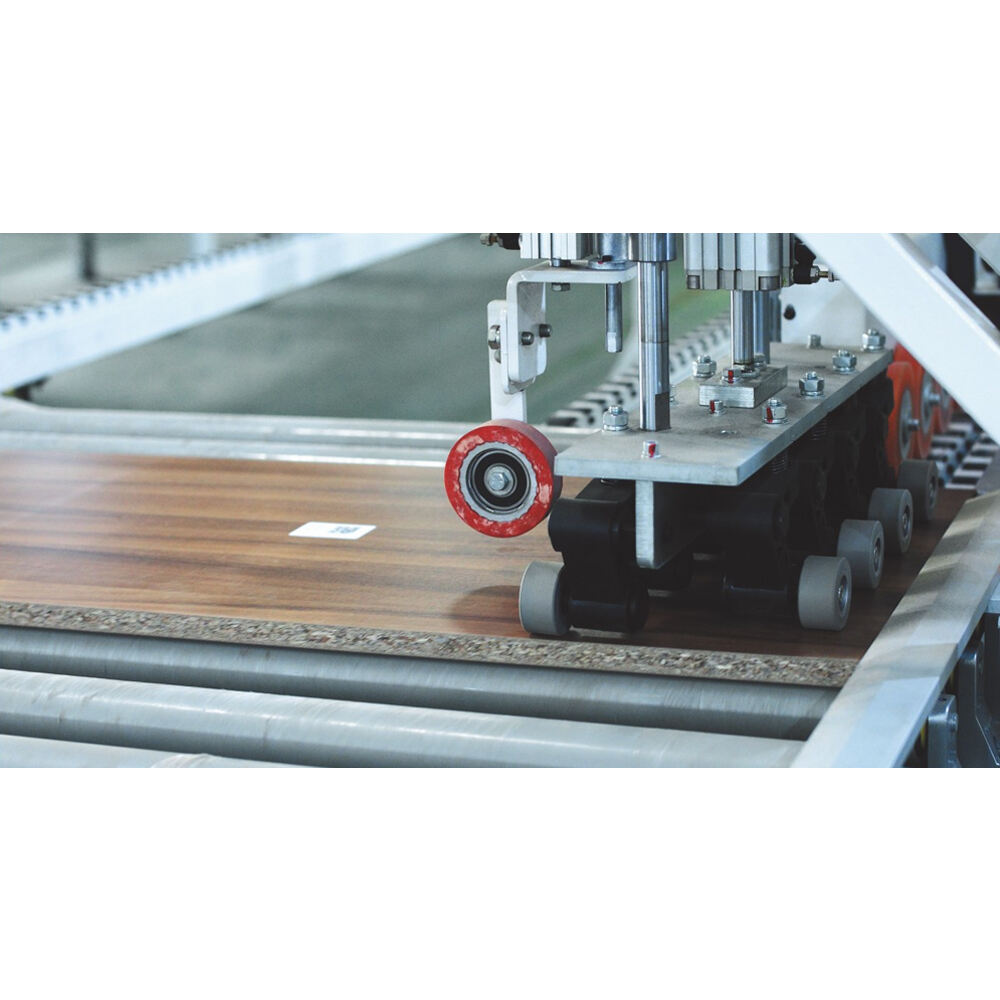

Here are some images of compliant automated conveyor systems installed in a Chinese furniture factory.

For wooden-made furniture, these machines have revolutionized the way Chinese factories take their wood from raw shape to final use in a piece of furniture. When automatically controlled, conveyor belts are made to perform loads of tasks effectively and process optimally; thus making it possible for the processing time as well as cost spent on labour too is very much minimized.

Types of Machines

Chain Conveyor Systems: These well-equipped systems make availability of chains to ensure an easy movement process for large elements into the straight path. They can be easily personalized for the manufacturing purpose and that is what makes them a top choice in the furniture sector.

Conveyor Systems - Belt conveyor systems work by moving products along a flat surface through motorized rollers. They are very good both for amateurs and experienced ones, it allows to work with various shapes of elements saving time.

Automated Guided Vehicle (AGV) Systems: AGVs are the robotic vehicles, which operate within a facility leading to independent material transport including pick and place operations as well. They can be zoomed for many other tasks as well, such carry furniture sections between assembly lines - which saves time on all production lines.

Screw conveyor systems: This type of conveyors in the escort rotation by screw mechanisms and hence send materials via a trough. Most common in furniture factories, pneumatic tubes are used to transport parts like lumber chips or sawdust from production point A to B.More suited for granular substances

Overhead Conveyor Systems These are conveyors that hang from the roof, and transport loads down in your factory. They are the best way of painting a good coats on to furniture items - although they form quite practical, and all their ability to help you build something really solid too is your friend when it comes down during the crucial stage for constructing up an item.

How Machines Help

In light of this, the introduction of these automatic conveyor systems has no doubt radically transformed the domestic furniture production sector. The implementation of these systems has reduced human interference and hence eliminates errors, ensures safety and reduces labor dependency to a considerable extent. Moreover, the customizable possibilities offered by these systems enable furniture fabricators to develop items whatever shape or size they desire faster than ever before and this is a great advantage in industry for fuelled innovation and adaptability.

Benefits of Automatic Conveyor Systems

Then, you can use a combined chain conveyor systems with right selection of drives which are suitable for up-and-down handling large furniture items.

Now lets take a look at the Belt Conveyor Systems: -Belt Conveyors are magnificently suited for huge assembly lines within upholstered and built-up furniture, as they have no adaptabilities so that you can set up your belt needs to place in line with whatever piece of upholstery is being produced.

AGV Systems: For fast furniture component transfer between assembly lines

The below features Sludge Cake & Wood Chips because those fragile materials would never caked into lumps per line so Let Manufacturer explains them.

Overhead Conveyor Systems: to safely convey furniture through the finishing process without fear of incurring damage

Improved Furniture Manufacture

Instead of employing migrant labour with automated conveyor systems migrants, the Chinese furniture factories have enhanced production by dint of higher quality products. With a few adjustments, they can be easily reset to suit the new production conditions which help them even more sustainable and efficient in the processes.